Do you have power quality issues on your network?

You may have experienced one of the following: frequent failure of equipment, reduced life of equipment, production losses, reduced safety levels of installations, increased carbon footprint or non- compliance with utility regulations. There are 3 significant sources of poor power quality caused by a variety of loads in customer installations.

- Harmonic pollution

- Load imbalance resulting in voltage imbalance

- Reactive power

High voltage distortion can result in equipment failure, production time and costly repairs to the electrical distribution network. If power factor correction capacitors are installed on the system parallel resonance can occur amplifying harmonics currents and the adverse effects on the network.

What are harmonics?

All non-linear loads create harmonics. A load which draws a non-sinusoidal (distorted) current, when a pure sinusoidal voltage is applied, is a non-linear load.

Typical sources of harmonics:

- Industrial loads (mainly 3-wire systems) AC & DC drives, UPS systems

- Commercial loads (mainly4-wiresystems) office equipment, computers,printers etc.

- The diagram shows an electrical waveform with harmonic distortion.

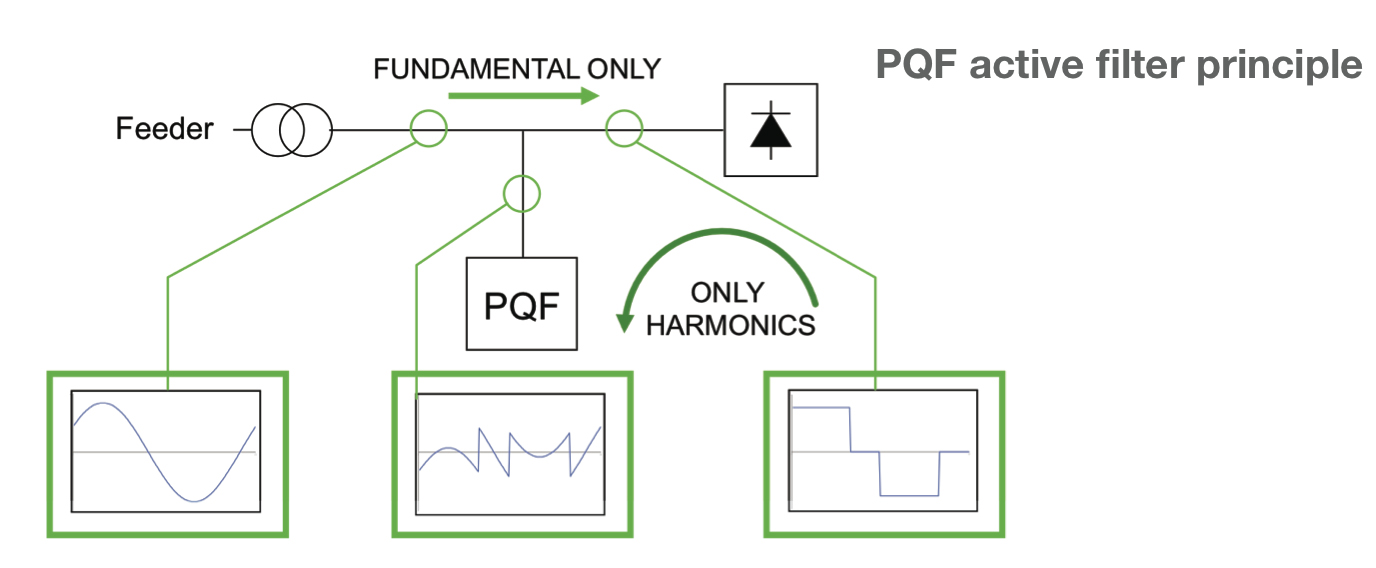

If high levels of harmonics are detected from a site survey, an ABB PQF active filter is utilised and installed in parallel to the polluting loads. The filter monitors the line current harmonics, as well as the requirements programmed by the user. For each harmonic frequency, the filter generates a compensation current in perfect phase opposition to the polluting current. It can also be used to perform load balancing and power factor correction as well. If high levels of harmonics are detected from a site survey, an ABB PQF active filter is utilised and installed in parallel to the polluting loads. The filter monitors the line current harmonics, as well as the requirements programmed by the user. For each harmonic frequency, the filter generates a compensation current in perfect phase opposition to the polluting current. It can also be used to perform load balancing and power factor correction as well.

The PQF active filter range is suitable for small or large applications (30 A - 3600 A) and do not get affected by changes in network impedance (transformer paralleling, switch to backup generator), providing perfect filtering results.

Arrange Your Harmonic and Power Quality Consultation

Understand how to quantify, characterise and measure harmonics on your system and what methods are available for you. With harmonic filter specialists on hand, IPD can supply, install and commission filters to suit your company’s requirements. We have partnered with ABB, a trusted leader in active harmonics to assist in managing any power quality issue.

Need our help? Click Here to Enquire |