When housed in cabinets or integrated as part of a machine, electrical and electronic equipment can be prone to malfunctions or faults due to overheating. The temperature and humidity levels inside electrical enclosures play a crucial role in determining the lifespan and performance of components. To mitigate this issue, implementing efficient airflow management solutions is essential to help regulate heat and humidity in enclosures.

The recommended average operating temperature inside a cabinet is 35°C, with no more than 60% relative humidity levels. When these limits are exceeded, it can lead to overheating, reduced performance, and even failure of sensitive electrical equipment. Excessive heat can also cause humidity to rise, leading to condensation and potential damage. Therefore, airflow management is crucial to maintain optimal operating conditions for electrical enclosures.

A key solution is the implementation of appropriate ventilation and cooling systems. This includes strategically placed fans, vents, and air filters to ensure a constant fresh air flow, preventing heat build-up inside the enclosure. Ventilation systems are designed to optimise the exchange of hot and cold air, helping regulate the cabinet's temperature and humidity levels.

Types of airflow management

|

Natural convection

Using an exhaust filter ensures the passage of air and the removal of heat by natural convection. This solution can be considered for dissipating low heat levels in dusty environments.

|

|

Forced convection

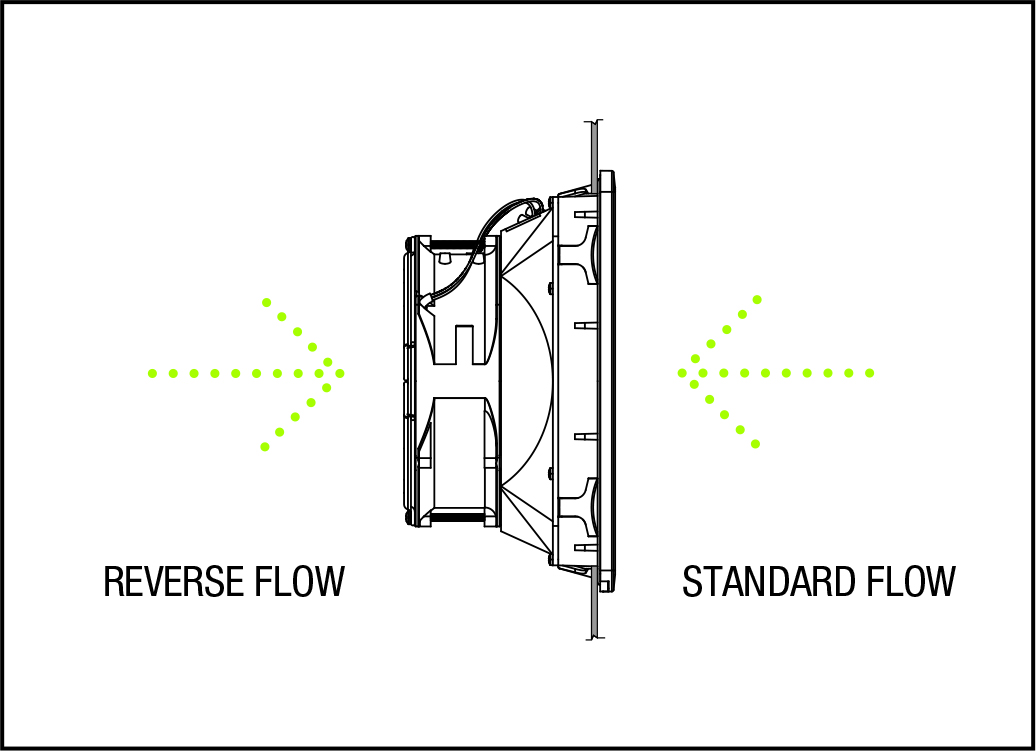

Forced ventilation is an inexpensive and efficient solution for preventing the formation of air pockets inside electrical cabinets. The best configuration includes fitting a filter fan with an exhaust filter. The filter fan is positioned at the bottom of the cabinet, sucking in filtered cool air from outside (standard airflow), while the exhaust filter at the top expels hot air. The increased air pressure inside the enclosure prevents unfiltered air from entering through holes or openings.

|

|

An inverted airflow version (reverse flow) is also available. A filter fan at the top and an exhaust filter at the bottom of the cabinet. The system can be controlled by a thermostat which turns the fan on when high temperatures are detected.

|

|

Hot air can also be extracted from the roof of the cabinet if, for instance, the sides of the cabinet are covered by obstacles, walls or the sides of other cabinets. In a perfect configuration, an exhaust filter is positioned at the bottom of the cabinet. The lower pressure generated by the roof unit draws in cold air from outside through the exhaust filter to enhance internal airflow and heat dissipation.

|

|

A swivelling fan is an alternative solution for better air circulation inside the electrical cabinet. This fan distributes heat to reduce the temperature, cools local hot spots and disperses cold air emitted by cooling units.

The filter fan is positioned at the bottom of the cabinet, sucking in filtered cool air from outside (standard airflow), while the exhaust filter at the top expels hot air. The increased air pressure inside the enclosure prevents unfiltered air from entering through holes or openings.

|

Airflow management is critical for maintaining the optimal performance and lifespan of electrical and electronic equipment housed in enclosures. IPD offers a range of solutions to efficiently manage heat and humidity, ensuring reliable and efficient operation of critical equipment. By implementing effective airflow management, businesses can minimise the risk of malfunctions or faults due to excessive heat and humidity, ensuring smooth operations and prolonged lifespan of their electrical enclosures.

For information on IPD’s range of thermal management solutions for enclosures, visit here: https://www.ipd.com.au/enclosures-and-climate-control/climate-control |