The biggest dangers in switch rooms are from arc flash events. An arc flash event is extremely dangerous due to the high temperatures it produces in the surrounding air. In most cases, it could heat up the air close to 20,000 ⁰C which could cause fatal burns to anyone in the vicinity of the electrical explosion. It is effectively like a bomb going off in the switch room.

Unless absolutely necessary, it is always good practice to stay out of switch rooms when the switchboards are live. If there is a requirement to be in there, the personnel should be well trained for that kind of environment, this is not always realistic though.

On some commercial and industrial sites, the switch rooms can sometimes have a high relative level of traffic, with maintenance staff continually locking off circuit protection devices, or making modifications to switchboards, and sometimes it is as simple as routine inspections. In this case, priority on the safe working environment of not only the switchboard itself, but also the switch room is paramount.

With ABB switchgear, we’ve got you covered. With the Reduced Energy Let Through (RELT) maintenance feature, anyone accessing the switch room can set the switchgear into “maintenance mode”, which drastically reduces the clearing time of the circuit breakers therefore vastly reducing the energy let though, making for a much safer environment within the room. This can be done via a switch outside the room, that would be switched on before entering, with a visual indicator in the form of a lamp on the switch plate or a flashing indicator. This feature could also be put into a parallel circuit with an electric door lock to the switch room door, preventing anyone from entering unless the system is in RELT mode. The sky is the limit with how this can be integrated into a site safety plan.

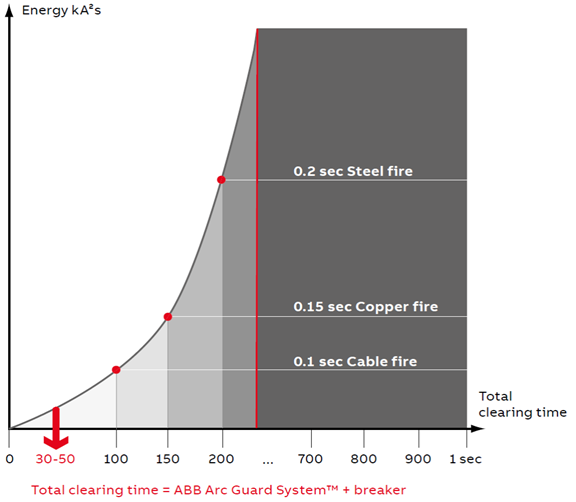

In addition to RELT, we also have the ABB TVOC Arc Guard System. This arc fault mitigation relay uses optical sensors to capture an arcing event and send a signal to the circuit breaker in under 1ms. The circuit breaker conveniently utilises the same input card for RELT signals as it does for TVOC signals. Once the signal from the TVOC is received (in under 1ms) the circuit breaker begins clearing the fault immediately. With ARC fault (high impedance fault) clearing times of between 30-50ms this drastically reduces extreme risk to personnel, as well as damage to the switchboard and switch room.

In these environments you should always have a safety plan where the need for personnel to be in the room whilst equipment is live is at the absolute minimum. However, in cases where it is absolutely necessary for personnel to be working close to or on live equipment, the system should be designed to significantly reduce any risk and damage that may occur.

This can be achieved with the switchboard design in mind, utilising arc fault containment as part of our Elsteel techno modular switchboard system, and in addition, using the technologies created by ABB switchgear. For more information contact your local IPD representative on 1300 556 601.